7D BIM Services (Project Lifecycle Information)

7D-BIM (seventh-dimensional building

information modelling) is used by managers in the

operation and maintenance of the facility throughout

its life cycle. The seventh dimension of BIM allows

participants to extract and track relevant asset data

such as component status, specifications,

maintenance/ operation manuals, warranty data etc.

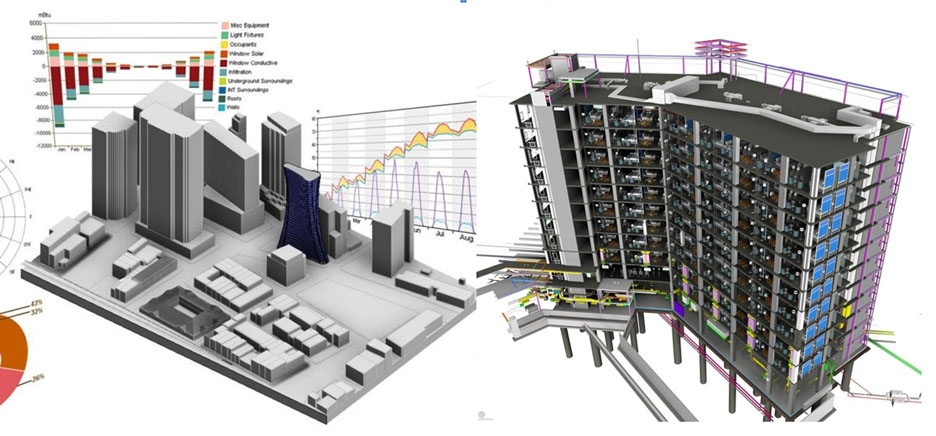

The utilization of 7D-BIM technology can

result in easier and quicker parts replacements,

optimized compliance and a streamlined asset life

cycle management over time. 7D BIM provides

processes for managing subcontractor/supplier data and facility component through the entire facility life cycle.

Sometimes referred to as integrated BIM or iBIM, 7D BIM involves the inclusion of information to support facilities

management and operation to drive better business outcomes. This data includes information on the manufacturer of a

component, its installation date, required maintenance, details of how the item should be configured, operated for optimal

performance, energy performance, along with lifespan and decommissioning data.

Adding this kind of detail to your information model allows decisions to be made during the design process - a boiler with

a lifespan of 5 years could be substituted with one expected to last 10, for example, if it makes economic or operational sense to

do so. In effect, designers can explore a whole range of permutations across the lifecycle of a built assets and quickly get an

understanding of impacts including costs. However, it is at handover, that this kind of information really adds value as it is passed

on to the end-user.

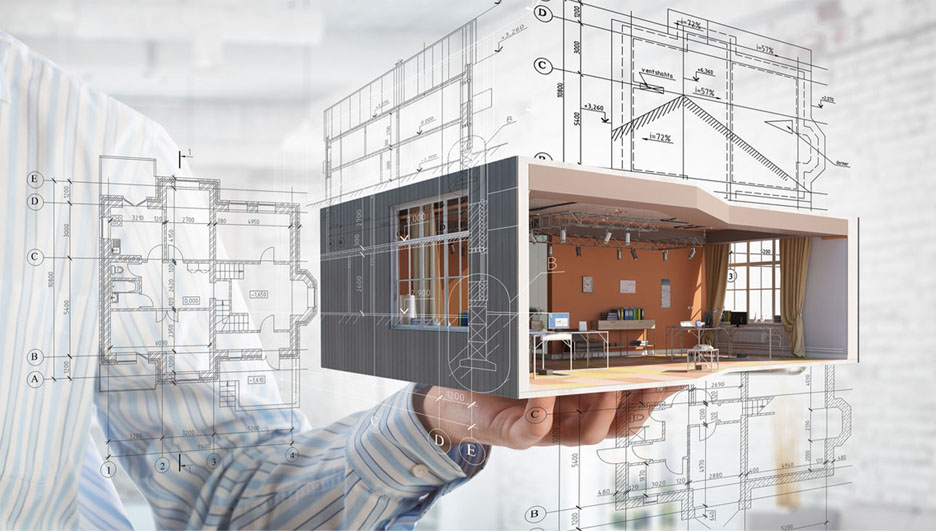

A model offers an easily-accessible and understood way of

extrapolating information. Details that would have been hidden in

paper files are now easily interrogated graphically. Where this

approach really comes into its own is in allowing facilities managers

to pre-plan maintenance activities potentially years in advance and

develop spending profiles over the lifetime of a built asset, working

out when repairs become uneconomical or existing systems

inefficient.

This planned and pro-active approach offers significant

benefits over a more reactive one - not least in terms of costs. Ideally

the information model should continue to develop during the in Use

phase with updates on repairs and replacements added in. Better

yet, a myriad of operational data and diagnostics can also be fed in

to inform decision making still further.