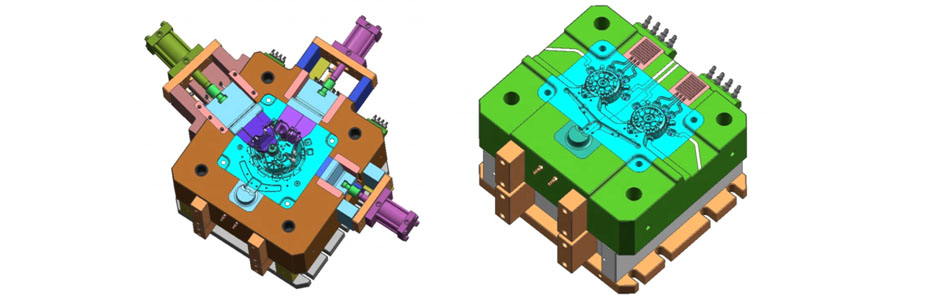

The longest path in product development is mould making and hence there is always a growing need to compress the time in making moulds. The most important phase of this activity is mould design, which needs good technology and expertise to design first time right moulds or minimize the number of iterations needed to build the right mould. 3D mould design is an extended activity of 3D part modeling. During the process of part modeling the factors influencing the mould design like parting surfaces, release drafts, profiles formed by slides and gating locations are considered. 3D part models formed with this consideration are the basic requirement to separate core and cavity models and slides. Cooling circuits, ejection systems, runner and gating systems are added with the core. We follow standard mould base like DME, HASCO, FUTABA, LKM to complete the mould design only in 3D model with Assembly views, Material list and part details as per the customer specification if customer requires Process chart, Electrode design.